The Seven Wastes

Introduction

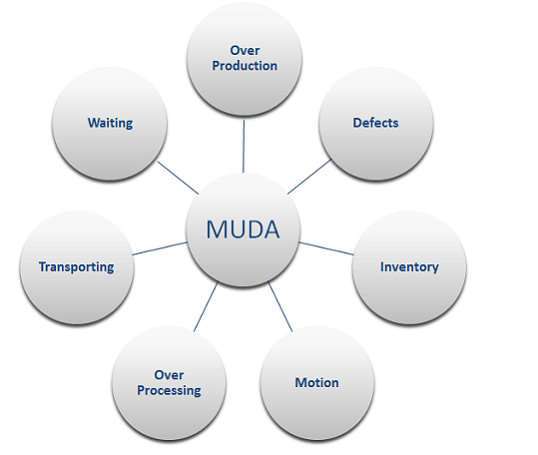

Waste elimination is one of the most effective ways to increase the profitability of any business. Processes either add value or waste to the production of a good or service. The seven wastes originated in Japan, where waste is known as “muda." "The seven wastes" is a tool to further categorize “muda” and was originally developed by Toyota’s Chief Engineer Taiichi Ohno as the core of the Toyota Production System. To eliminate waste, it is important to understand exactly what waste is and where it exists. For each waste, there is a strategy to reduce or eliminate its effect on a company, thereby improving overall performance and quality.

1) Overproduction

Overproduction arises when the company is producing more than the customer really requires. This may include both the production of products or components for which there are no orders, as well as production of more items than currently needed. This is the worst kind of waste, because it usually multiplies other kinds of waste. It increases rework rate, inventory, processing, waiting, as well as unnecessary motion and transportation.

The simple solution to overproduction is turning off the tap; this requires a lot of courage because the problems that overproduction is hiding will be revealed. The concept is to schedule and produce only what can be immediately sold/shipped and improve machine changeover/set-up capability.

2) Defects

Parts or units that do not meet the customer specification. Defects always require some degree of additional attention, whether it they are scrapped, reworked, or repaired. Defects are caused by bad manufacturing processes (caused by human or machine errors). These take additional time and therefore increases manufacturing costs of the final product, and may results in more wastes or other of the seven wastes.

3) Inventory

Inventory is the quantity of items on stock, which are required to manufacture a product. These goods also cause costs to the company. When they are not used they tends to hide problems on the plant floor, which must be identified and resolved in order to improve operating performance. Excess inventory increases lead times, consumes productive floor space, delays the identification of problems, and inhibits communication.

Competitive organisations make sure that their system controls the inventory, so that resources are not being wasted on unwanted items or build groups.

4) Motion

Unnecessary movements occur when employee is moving around his work space and as a result of this may waste time and effort. All kind of unnecessary motion is being caused by poor working standard practices, poor (not optimal) process design or work area layout. Excessive movement causes extensive processing time due to walking, lifting, and reaching, may cause unnecessary fatigue and long term injury, delays communication.

Jobs with excessive motion should be analyzed and redesigned for improvement with the involvement of plant personnel.

5) Overprocessing

Overprocessing includes extra steps in the manufacturing process. It can also mean producing products of a higher quality than required. This may be due to incorrectly used equipment, errors in rework process, poor process design or bad communication. This can be also result of not checking what are the real customers’ requirements.

6) Transportation

This includes the unnecessary movement of information, products or components from one area to another. Unnecessary transport usually occur together with unnecessary movement, product damages, lost parts and systems, which detect movements. Excessive movement and handling represent an opportunity for quality to deteriorate.

Transportation can be difficult to reduce due to the perceived costs of moving equipment and processes closer together. Furthermore, it is often hard to determine which processes should be next to each other. Mapping product flows can make this easier to visualize.

7) Waiting

Whenever goods are not moving or being processed, the waste of waiting occurs. Typically more than 99% of a product's life in traditional batch-and-queue manufacture will be spent waiting to be processed. Much of a product’s lead time is tied up in waiting for the next operation; this is usually because material flow is poor, production runs are too long, and distances between work centers are too great. Goldratt (originator of the Optimized Production Technique, the Theory of Constraints) has stated many times that one hour lost in a bottleneck process is one hour lost to the entire factory’s output, which can never be recovered. Linking processes together so that one feeds directly into the next can dramatically reduce waiting.

8th type of waste: Unused creativity

This waste involves lost of time, skills, ideas, improvements and learning opportunities by not taking employees opinion into the account. This is result of employees not taking part in design of manufacturing processes. Only in this way the ideas can develop, which are needed to eliminate and avoid the other seven waste sources. This helps to improve the processes in continuous manner by increasing the available knowledge and creativity of employees. In addition it helps in principle to increase the level of employees satisfaction at work.

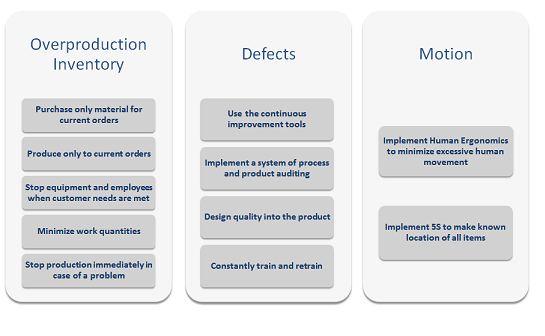

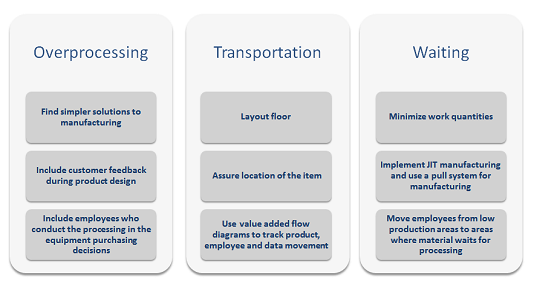

To better understand how to reduce the seven wastes look at the tables below,

or download in pdf.

Free inspired from:

www.emsstrategies.com

www.manufactus.com

www.quality-assurance-solutions.com