Introduction

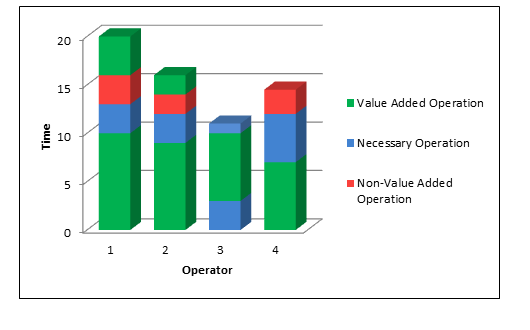

A Yamazumi chart (or Yamazumi board) is a stacked bar chart that shows the source of the cycle time in a given Process. The chart is used to graphically represent processes for optimization purposes.

Overview

Yamazumi is a Japanese word that literally means to stack up.

Process tasks are individually represented in a stacked bar chart, these can be categorized as either Value Added, Non-Value Added or Waste. The mean duration time of each task is recorded and displayed within the bar chart. Each process task is stacked to represent the entire process step.

The axes of the Yamazumi chart are as follow:

y axis represents cycle time.

x axis represents each process step.

Often, a target cycle time (mean cycle time) will be plotted to aid line balancing activities.

The Yamazumi chart can be used for both process Waste Elimination or Line Balancing activity. Process steps can be rearranged or deleted to optimise and balance the target process.

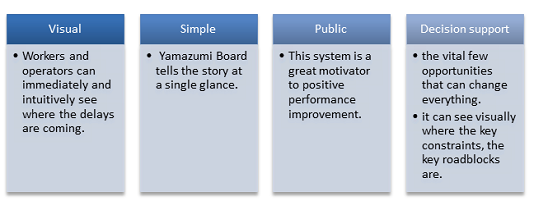

The tool is intended to support Business Process Improvement teams, it is also a useful Lean training aid.

Yamazumi charts are used by Lean improvement teams throughout many process driven organizations.

Benefits

The Yamazumi board provides a mechanism to quickly rebalance a process when takt changes, and allows a visual indication of which operations are overloaded (beyond takt), and which are underutilized.

The Yamazumi chart is a great visual tool to show where delays, wastage and blocks are happening

You can simulate and do exercises